Matching Your Diamond Tool with the Right Material

Diamond cutting tools are effective in cutting materials of varying thickness and texture. They are used extensively because they are quick and easy to operate while producing accurate results.

However, just like any tool, diamond cutting blades get worn out. If the metal wears away too quickly, the diamond particles get torn out of the metal bond resulting in chips and breaks – shortening the service life of the tool. If the metal wears away too slowly, the diamond particles wear away before a new diamond is exposed, resulting in a dull blade.

Matching the correct diamond saw blade to the material is vital, to extend the service life and produce the best results.

Types of Diamond Saw Blades

The two most common causes of wear and tear in diamond saw blades are overheating and dust or debris build-up. Diamond saw blades are designed for wet or dry applications to cool down the tool and remove dust or debris. The wet application uses water while the dry application uses air from the cut-out spaces of the blades.

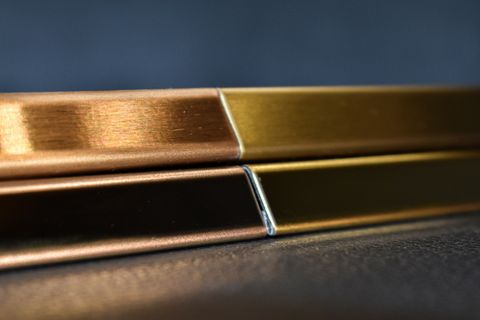

Continuous Rim- Continuous rim blades have a solid, continuous edge that typically has soft bonds and used in wet applications. Water is used to cool down the blade and wash off any dust and debris to lessen the friction and build-up in between the gaps of the tool. Out of all the blades, continuous rim blades cut the slowest but also the smoothest. They are ideal for cutting hard materials such as stone, marble, granite, porcelain tiles, ceramic tiles and glass, which require a clean finish.

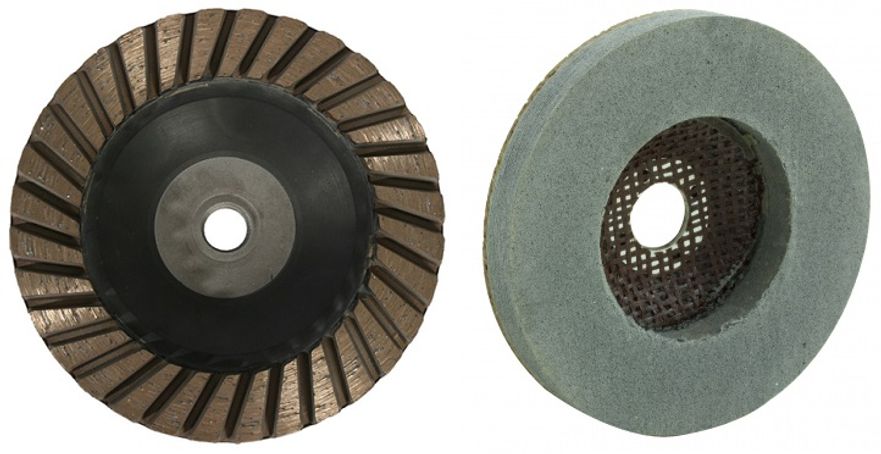

Segmented Rim- Segmented rim blades have a serrated, continuous edge that typically has medium to hard bonds and are used in either wet or dry cutting. The sizes of the cut-outs or segments vary from blade to blade which depends on the materials being cut. The spaces between the cut-outs or segments are called gullets and cools down the tool and blows out the dust and debris. Segmented rim blades utilise a fast but relatively smooth cutting action that can cause chipping. Out of all the blades, segmented rims are the most durable. They are ideal for cutting reinforced concrete, brick, limestone and masonry/blocks that do not require an extremely polished finish.

Turbo Rim – Turbo rim blades have a finer serrated, continuous edge that typically has soft to medium bonds and are also used in either wet or dry applications. The blades combine and enhance the advantages of the continuous and segmented rims. Turbo rim blades are faster than continuous rim blades and have smaller interweaving segments than segmented rim blades. They are ideal for cutting concrete, brick and limestone materials that produce a lot of dust and debris.

Understanding the types of saw blades and its suitable application allows the worker to cut quickly and easily. Not only does this extend the life of the diamond cutting tool, but it also guarantees the most accurate results.

Extending the Life of Your Diamond Blade

Aside from using the right type of diamond blade on a certain surface, proper maintenance increases the lifespan of the blade and saves the business on the cost of buying additional tools.

Cleaning

The use of soap or cleaning solutions isn’t necessary when cleaning a diamond blade. Manufacturers of diamond tools in Australia recommend running the blade against the surface of a concrete or cement block. Doing so sharpens the blade and removes accumulated dust and debris. Lubricants also prevent rust from building up on the metal body of the blade.

Storage

Diamond blades need to be stored away from surfaces that can dull or ruin their edges. Pegboards keep the blades away from hard surfaces and allow workers to easily find and obtain the specific tools they need. There’s also the option to store blades in tool drawers, but it’s important to ensure that their edges don’t hit the interior.

The temperature of the storage area also plays a factor in a diamond blade’s lifespan. Keep the tools in places with low humidity to make sure that rust doesn’t accumulate on the metal body. If necessary, use a dehumidifier to control the air quality.

Shop and Stock on Diamond Tools with Ease

Amark Group is a trusted provider of sharp and durable diamond cutting tools. We offer an expansive range of tools and equipment used in various industries. We are committed to present clients with a wide of source of high-quality products manufactured by global brands and excellent customer service that allows them to shop and stock with ease. We service various companies throughout Australia through our long list of distributors.

Looking for diamond tools? Talk to us today, we supply businesses and industries.